After talking shop with Ship Shape John it was time to do as the power point presentation stated and that's...

Get busy!

All our classes are

VERY HANDS-ON!

In fact over the years I would say that is the most

common compliment and

feedback we receive about our classes and that is there's not much sitting around time... most of the time you're on your feet working and learning.

Next up...

How to remove oxidation

The first thing we do is discuss the two general categories of boats, that would be,

- Painted

- Gel-coat

During the power point presentation we go over how these two types of finishes are very different and it is of the utmost importance to know which type of finish you're working on otherwise you will make a VERY costly mistake. I explain what the risk is when you make a mistake and how to avoid the risk to save yourself a lot of headache and expense.

Once we cover painted versus gel-coat hulls we move onto how to work on gel-coat hulls.

Now there's all kinds of ways to remove oxidation but my goal is to always show people the easiest way to do it while getting the best results.

When it comes to removing oxidation, most people think the best and fastest way to do this is to use a rotary buffer with a wool pad and an aggressive compound.

And that's how most of the industry does this type of work.

No me.

Removing oxidation with a rotary buffer and a wool pad means PUSHING HARD against the boat for hours and hours. It's incredibly hot, hard work.

What I show for medium and severe oxidation is how to reach the same goal by doing a whole lot less work and a whole lot less pushing a rotary buffer hard against the side of a boat hull that also by the way is at an angle pointed away from you making the process even more difficult using the traditional approach.

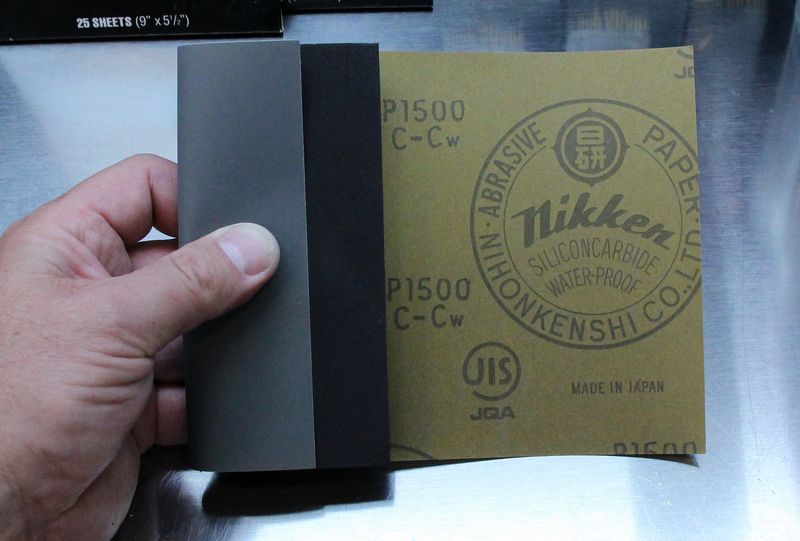

First up, I show the simplest known way to remove oxidation and that is to hand sand using a simple flexible hand backing pad with an extremely high quality sandpaper. I explain why it's important to use the highest quality sanding products you can obtain as there are 4 strong reasons.

Restoring an oxidized gel-coat boat

Restoring an oxidized gel-coat boat

This is the

advanced part of the class and this also tends to be the portion of the class most guys are interested in learning about. There are no books, videos or other boat detailing classes that I'm aware of where you can get this type of very specific information and the techniques to do this type of work correctly.

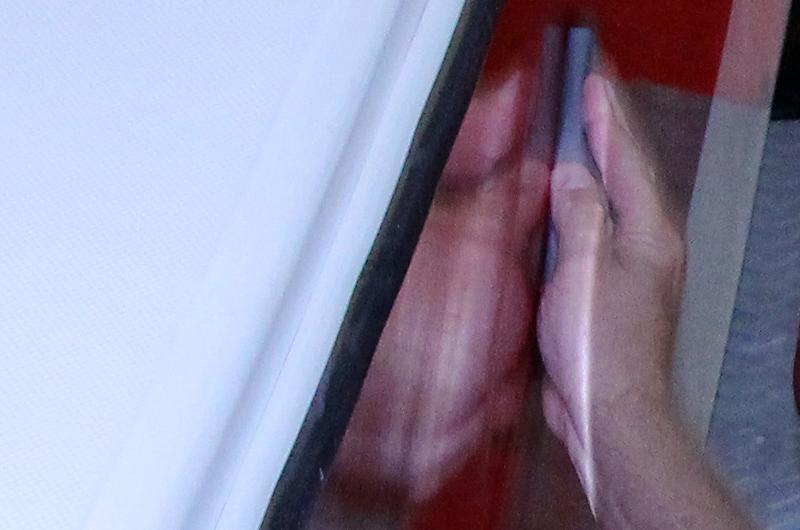

I always show two ways to hand sand starting with how to wrap a backing pad....

Followed by the correct way to move your sanding pad over the surface. There's a right way and a wrong way. There's also hand speed and pressure to be aware of as well as how long to sand.

Next I show an easier way to hand sand... a much easier way...

These guys are laughing now while I'm doing all the work but they won't be laughing when it's their turn!

Next up is the easiest way to sand and that's to machine sand. This portion of the class goes over how to use both air sanders and electric machine sanders safely as well as the correct techniques for machine sanding.

Machine Compounding

Machine Compounding

After sanding it's time to remove your sanding marks. This can be done a number of ways but I show the fastest way and that's using a rotary buffer with a wool pad and a high quality compound.

You're always going to want and need a rotary buffer when working on oxidized boats but the amount of work needed to remove sanding marks is FAR LESS than the amount of work to use the old way of compounding for hours and hours.

Techniques for using a rotary buffer

Techniques for using a rotary buffer

The rotary buffer can be a friend or a foe, it all comes down into how you hold the tool and we go over that in the class too....

That's red pigmented gel-coat or polyester resin you see on the face of the wool pad. That's normal and to be expected.

Whenever you're doing compounding work you'll have two things building up on the face of your pad and we go over why it's important to work clean and then how to clean your pads as you work around the boat.

Next it's time for the class to start sanding and buffing.